When trying to determine FDA medical device classification, there are a few ways to get information and feedback from the Agency. We are often asked how we choose between a Pre-Submission Request for Feedback (part of the Q-Submission Program) or a 513(g) Request for Information when determining medical device classification. While both can provide valuable information, we have listed some of the distinctions of each below that help drive the decision. We won’t call any of these “pros” or “cons” because it depends on the goals of our clients and the nuances of the particular medical device.

Clarity on Device Classification through a Pre-Submission (Pre-Sub):

- Nothing that the FDA or the company says is binding.

- You cannot directly ask for the classification of your device in a Pre-Sub but you may be able to ask similar questions that would give you insight on a classification. For example, you may propose a predicate device and then ask “Are there concerns with the predicate device proposed?”. If no concerns are raised, this could be an indication the predicate could be used to prove substantial equivalence in a future 510(k) submission.

- There are no user fees for a Pre-Sub request.

- A Pre-Sub generally allows for 3-4 questions/topics.

- A Pre-Sub allows an opportunity for a teleconference or in person meeting.

- Response time for a Pre-Submission is 70 days (or 5 days prior to the scheduled meeting, if requested) and our recent Pre-Subs have all fallen within this time frame.

- After a Pre-Sub teleconference draft meeting minutes must be submitted to FDA as an amendment within 15 days.

- FDA may still suggest a 513(g) Request for Information.

513(g) Request for Information:

- While the decision is like a Pre-Sub and also non-binding, FDA will typically stay consistent with their proposed classification/response if there are no substantial changes later.

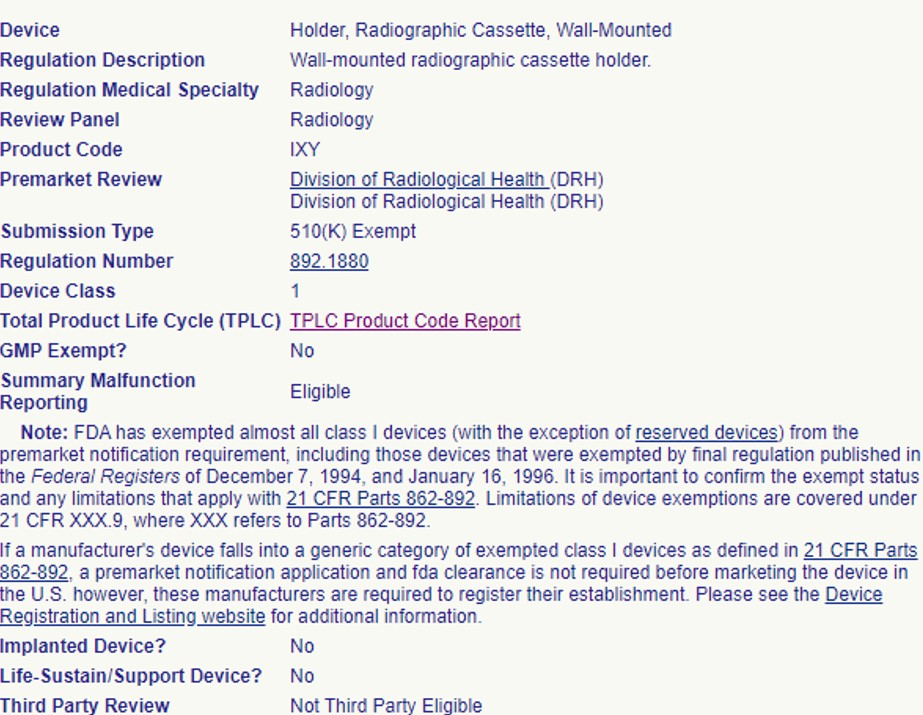

- If FDA gives you a product code/classification opinion for your device (assuming that one exists) you will have a potential path to market.

- There is a user fee associated with a 513(g) ($6,528 standard or $3,264 for small businesses* in fiscal year 2024).

- 513(g) requests do not offer the flexibility to ask questions on multiple topics or have any live dialog with FDA as the response is a written-only response.

- Response time for a 513(g) is intended to be within 60 days of receipt. (Important note: this timeline has not been met on any of our recent submissions).

- Requires draft labeling.

- FDA may still suggest a De Novo or PMA submission if a classification does not exist.

Both 513(g) and Pre-Submission requests have FDA-prescribed formats. CMD can help you balance the business and regulatory risk of these different pathways in addition to authoring the submissions and supporting the FDA interactions.

*Note that applying for “small business designation” with FDA requires 60 days to process and must be completed before you can leverage the small business pricing. Plan ahead!